Below are some of the main steps in the woollen manufacturing process. They did not always follow the illustrative sequence below, and some steps could involve alternative or additional activities.

1. Sheep shearing

Sheep are usually shorn in the spring, producing a fleece of two to eight kilos, of which 30-70% can be grease, dirt and dried sweat (‘suint’). The preferred breed for the Langholm woollen industry was the Border Cheviot.

2. Wool grading and sorting

The fleece is broken up into different qualities of fibre. Wool from the shoulders and sides are typically used for clothing; wool from the lower legs for blankets. The British grading system is based on:

- Style: determined by length, crimp, fineness, handle and lustre.

- Characteristics: including colour, strength and uniformity.

3. Scouring

The wool is cleaned in alkaline baths, capturing by-products such as lanolin (wool fat).

4. Dyeing

Colouring by immersion in a dye can be done at this stage (with more permanent results: hence ‘dyed in the wool’) or at a later stage (piece dying), depending on the desired pattern.

5. Carding

The fibres are straightened, formed into slivers and wound into threads.

6. Gilling and combing

This removes shorter fibres and rearranges longer fibres for high quality worsted yarns. The term ‘worsted‘ is derived from the village of Worstead in Norfolk, where many Flemish weavers settled in the 12th century. Threads for non-worsted (‘woollen’, lower quality) yarns do not go through these processes.

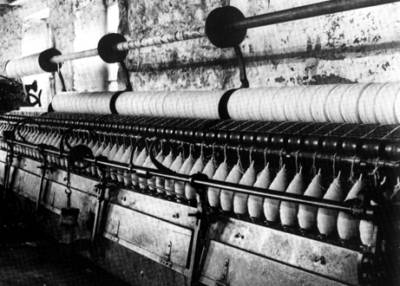

7. Spinning

This combines threads into strands and then ‘yarns’ (combinations of strands). Woollen (non-worsted) yarns were made using a spinning ‘mule’, a machine that used a hybrid of two earlier technologies (a ‘mule’ otherwise being the offspring of a horse and a donkey). Worsted yarns could be spun using a wider range of machines.

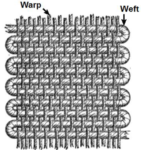

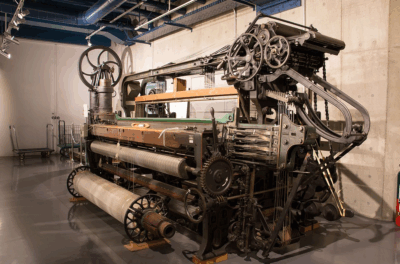

8. Weaving

The yarn is woven into fabric using an electrical ‘power loom’, as distinct from a human-powered ‘hand loom’. Longitudinal yarns (the warp) are combined with cross yarns (the weft) to produce patterned fabrics.

Looms use shuttles which pass left and right to create the cross yarns (weft). A popular brand of power loom was Dobcross, made by Hutchinson, Hollingworth & Co., near Dobcross in the Manchester area.

The looms were controlled by metal punch cards (a precursor to modern computer systems). One type of control system was a Jacquard machine.

9. Finishing

Finishing can include fulling (immersing in water to make the fibres interlock), crabbing (permanently setting interlocked fibres) and decating (shrink-proofing).